What is RS Production OEE?

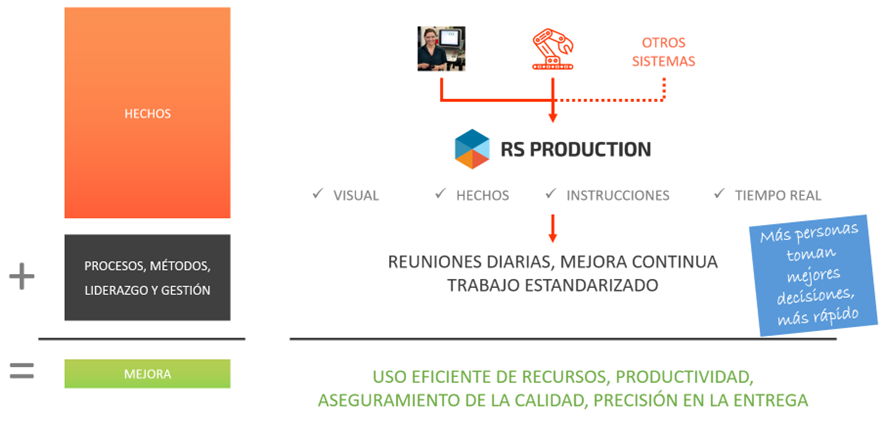

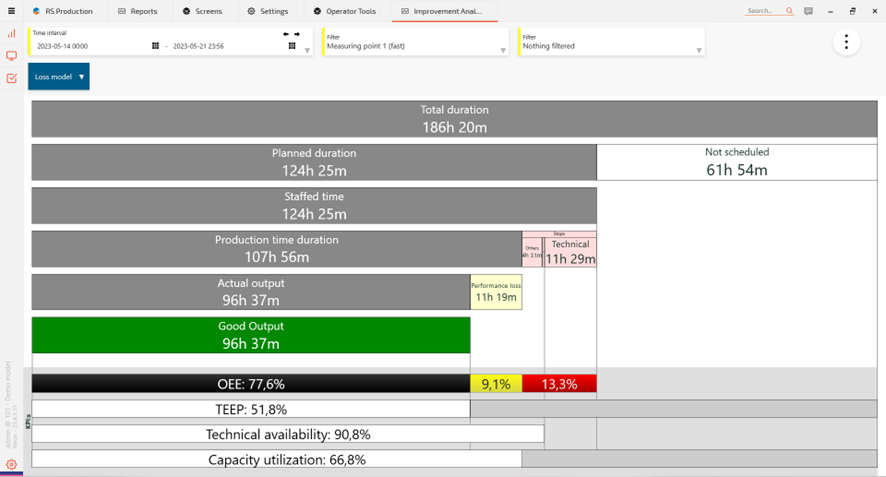

The measurement of OEE (Overall Equipment Efficiency) and other KPIs is crucial for Production Areas to achieve global efficiency standards.

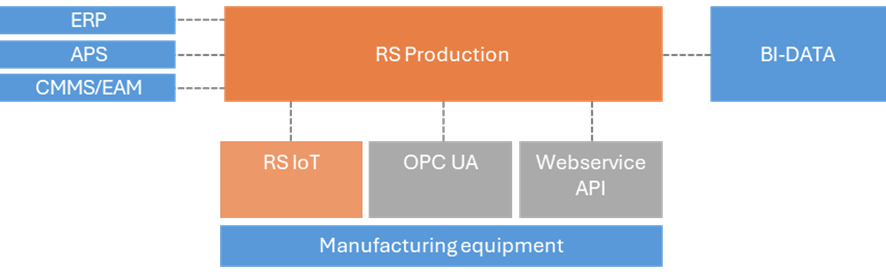

RS Production is an IoT platform that directly receives data from production lines, operators, and other systems to transform them into actionable real-time information.

Benefits

- Reduction of production costs by using fewer resources per unit produced.

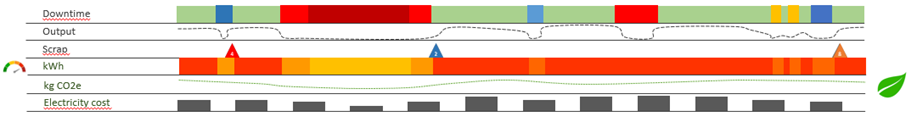

- Automatic identification of losses in real-time.

- Insight into production losses by visualizing real-time data.

- Understanding machine and operator data.

Key features

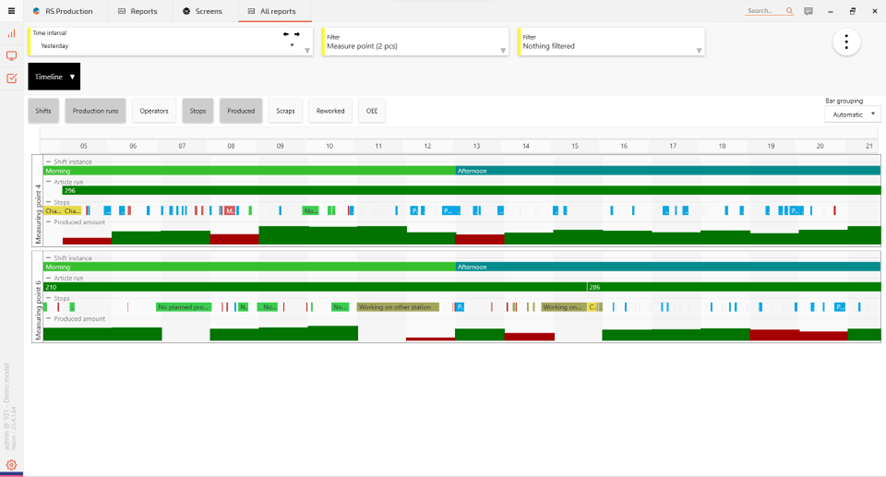

- Ready-to-use real-time reports for daily meetings, continuous improvement, production management, and more.

- Easy collection of production data from operators and machines.

- Expansion to additional functionalities and scalability to more machines and factories as needed. This includes the ability to incorporate measurements of energy consumption, CO2, checklists, quality controls, andon, etc.

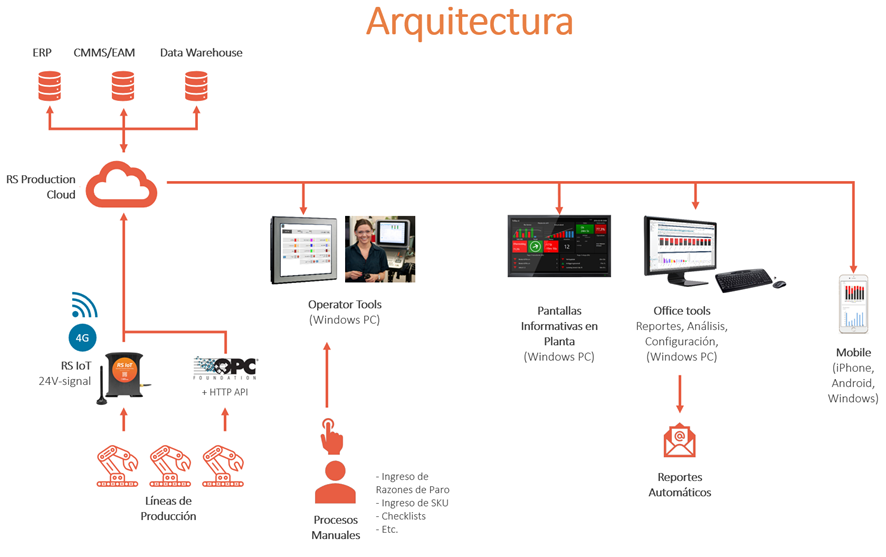

How do we connect to the production lines?

For the connection to the production lines, we include our RS IoT hardware in the price, which has the capability to receive signals from sensors, PLCs, contactors, and relays. The equipment has dual communication capability, either through the cellular 4G network or connected to the plant’s Wi-Fi.

If the plant’s automation systems allow, we can connect to the PLCs via the OPC protocol by installing a Kepware or similar software.

This information is sent to the RS Production cloud servers, where it is enriched with data provided by operators, such as downtime reasons, rejection reasons, the product being manufactured, etc.

Peripheral devices like plant information displays, mobile phones, or PCs for analysis and reporting access the cloud to retrieve data converted into information that facilitates real-time decision-making.

Operator Tools

Operators have access to a user-friendly visual interface that allows them to report real-time information, such as reasons for losses, current products being manufactured, production plans, shift objectives reports, etc. Additionally, they have a preliminary level of analysis and real-time visualization of their results.

Plant Information Displays

Throughout the entire production plant, screens can be configured quickly and easily (without the need for programming). These screens come with a set of over 25 reports that enable the visualization of tracking results, improvement actions, PDCA (Plan-Do-Check-Act) cycles, etc.

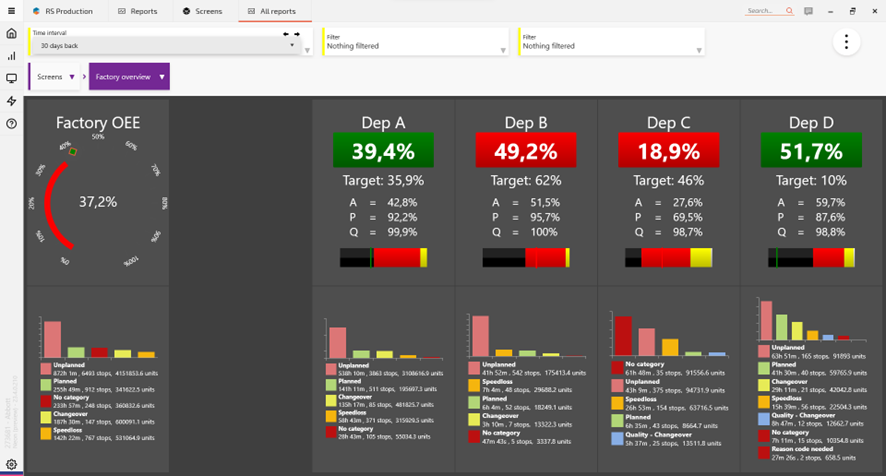

Office Tools

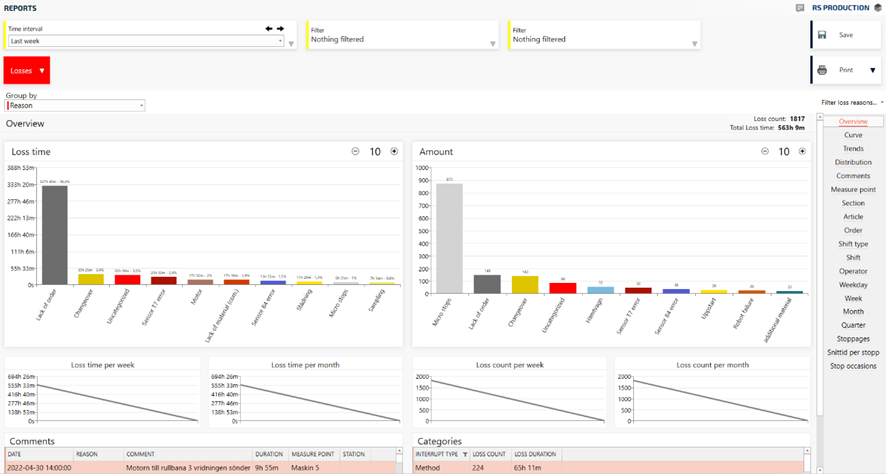

For profiles such as supervisors, managers, or team leaders seeking greater depth in the analysis of production results, a suite of over 50 reports is available, including:

- Pareto Charts.

- OEE Waterfall Diagram.

- Cycle Time Analysis.

- Process Change Matrix.

- Various filters and classifications.

- Automatic email reports and printouts.

Mobile Application

Get live production data at your fingertips with mobile devices, including:

- OEE Measurement.

- Push notifications for deviations.

- Messaging system (chat).

- Support for iPhone, Android, Windows.

Integration

The commonly requested integration capabilities include:

ERPs, MES, EAM, CMMS, etc.-We offer both unidirectional and bidirectional integration through REST API, SFTP, SQL, or CSV import.

Sistemas de Visualización BI.-Our platform supports integration and data export to popular tools such as Power BI, Tableau, Qlik, etc., maximizing return on investment.

Striving to generate the maximum return on investment

RS Production offers additional applications such as:

RS Energy.- It allows the incorporation of energy consumption and CO2 emissions variables into the analysis, enabling the identification of consumption patterns per production line, product, shift, etc.

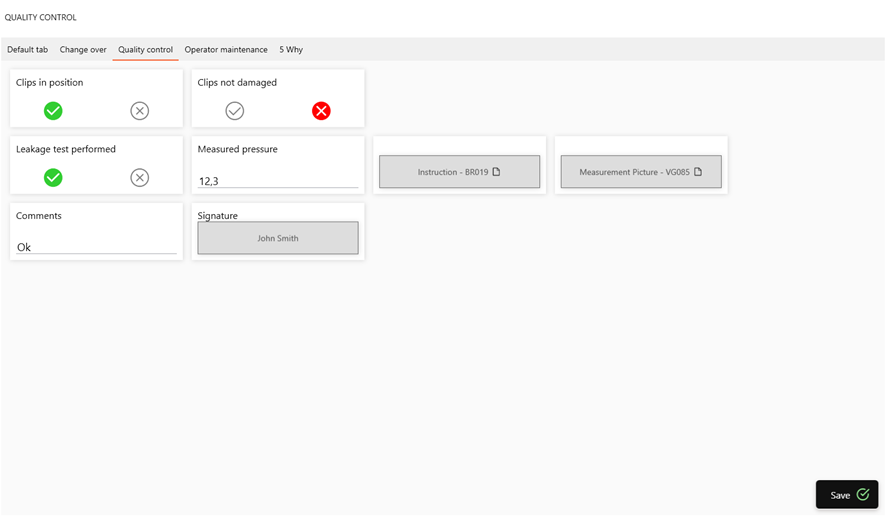

RS ACT.- Automatically present instructions, checklists, and appropriate operator routines based on production events such as new shifts, changes, quantities, and more.

If you are interested in a free product demo to test it for up to 45 days in your plant, please inquire for more details or contact our sales team to arrange the trial.

Contact

us.

For more information about our products

and services, please contact us at:

[email protected]

+51 977 967 376

Vertix Technologies SAC

Av. José Larco 1232

Lima 15074

Peru

©2023 Vertix Technologies. All rights reserved.

Privacy policy